RHK-AK

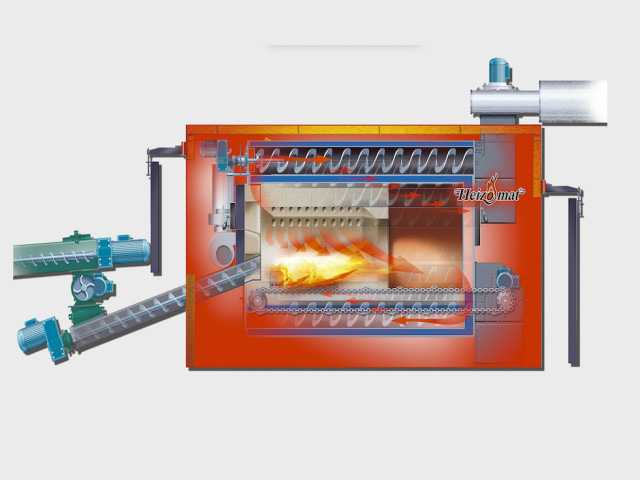

The RHK-AK series can produce 30 – 1490kW and is ideal for farms, hotels, and industry scale large biomass heating plants. The RHK-AK boiler is the preferred boiler for industrial uses due to its flexibility with fuel type and quality. It can burn a wide range of materials including G50 wood chip, wood shavings, pellets, rape-straw and miscanthus. Fuel is automatically fed via high-tensile steel augers from the fuel store to the combustion chamber, with any residue automatically transported to the ash bin. Foreign bodies, such as nails, are easily cleared out of the fire chamber by the robust de-ashing system. The heat exchangers have automatic cleaning augers which are regularly in operation, while also acting as turbulators to reduce the soot emissions from the boiler, even when the boiler is at peak-load.

RHK-AK boilers come with lambda and vacuum control as standard, for optimum combustion and safety. All RHK-AK boilers can operate using either a single or 3-phase power supply, so there is no need to change the existing site supply.